Shell and tube heat exchangers OIL-WATER 1 Pass

The oil-water heat exchangers are the most usual in the industrial world using the water as principal and most efficient form of refrigeration.

This heat exchangers are manufactured with finned copper tubes producing a high heat transfer, both liquids are separate by the tube wall avoiding the contamination between them and when more colder the water is more smaller the heat exchanger and faster and more easily the thermal energy going through hot liquid to a cold liquid.

The principal advantage of PILAN Heat exchangers is that the tube stacks are floating and removable, this means that it is easy replacement and cleaning.

They have hot brass or bronze end caps, avoiding rusty and making for easier removal the pipes.

PILAN heat exchangers are manufactured from high quality materials.

Each and everyone of them is hydraulically tested and with CE mark certificate.

We manufacture heat exchangers with one, two or three pass end caps, depending the your needs, and with copper tubes for use with fresh water or copper/nickel tubes for marine applications with sea water.

The one pass heat exchangers dissipate about a 30% less than 3 Passes, but you have the possibility to put a bigger cold water flow.

These one pass heat exchangers are used in marine applications because you have a big quantity of sea water, reducing the heat exchanger size.

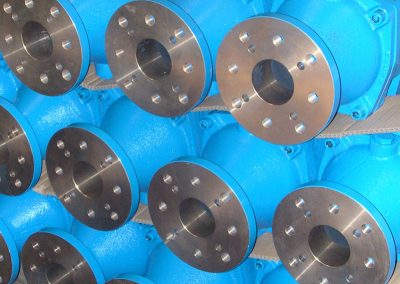

These heat exchangers have the cooling water inlet and outlet ports on opposite sides and these ports can be for rubber hose clamp connections, thread BSP connections, and flanges connections for series D-E and F like you can see in the Specifications pages.

These heat exchangers can be used in marine applications, boats, and mining too with salt water, the only change in which case the tubes is copper/nickel, rather than copper, all others components are always the same, only you need to specify in the reference letter “M” for Marine application.

We manufacture our PILAN heat exchangers, for special applications with Stainless steel tubes stacks AISI-316.

Fields of application: Power pack units, rubber and plastic injection machines, oil hydraulic presses, lift vehicles, compressors, mining, boats, etc.

See Specs: